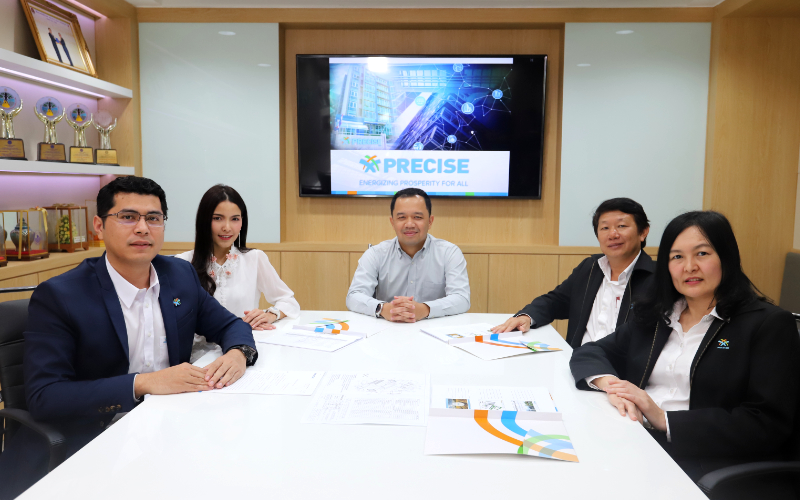

Precise Electric Manufacturing Company Limited (PEM)

PEM also takes care and provides maintenance services for systems and equipment. We apply our expertise and knowledge in the field to help clients manage the energy for the highest efficiency. Our talent includes understanding problems and solving them quickly for the success of your projects.

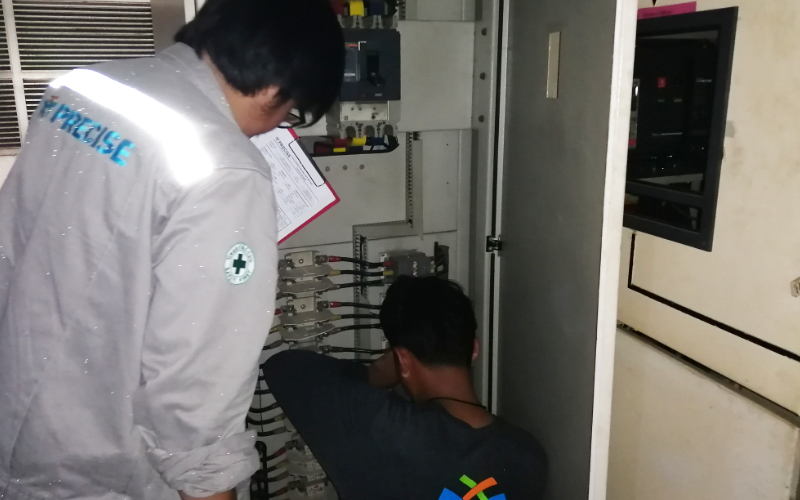

Professional Team

We have teams of skilled people who have been trained to enhance their potential and certified by the leading energy institutes.

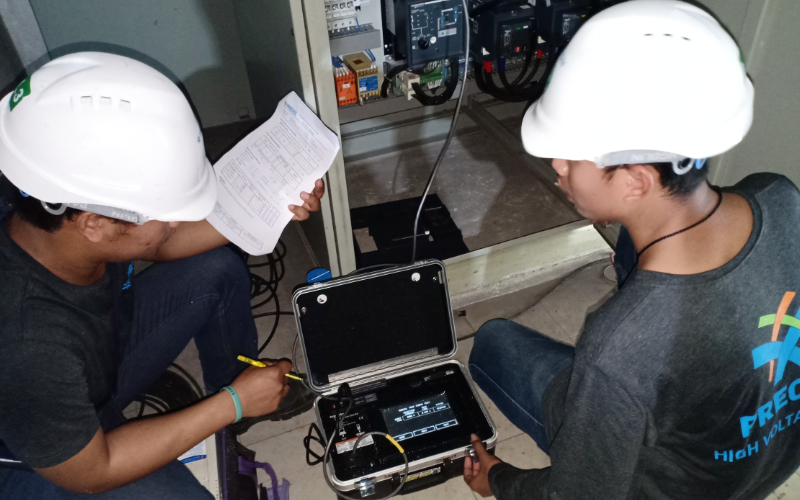

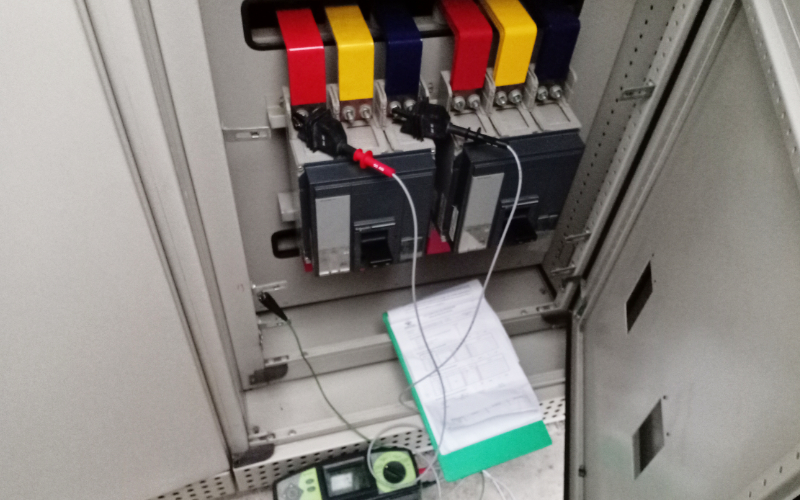

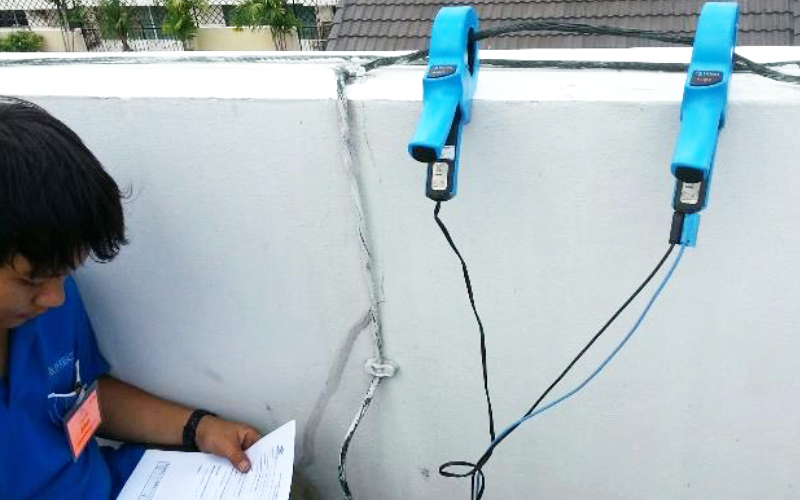

Tool and Test Equipment

We are readily equipped with special tools and test equipment to resolve problems quickly and professionally.

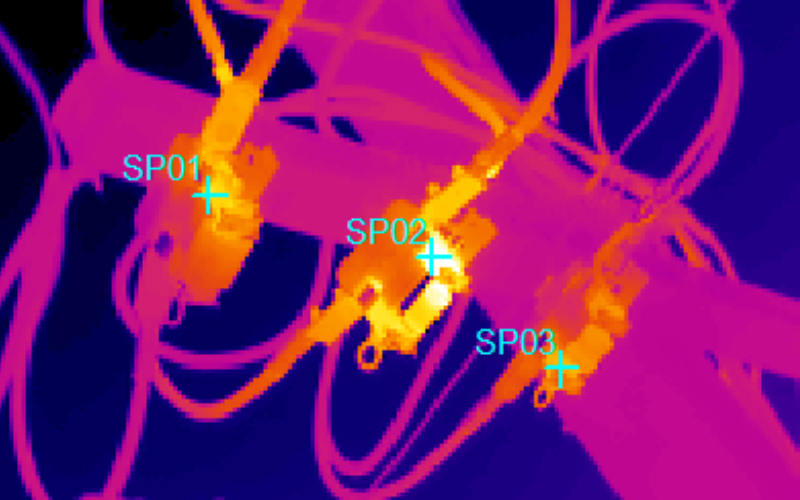

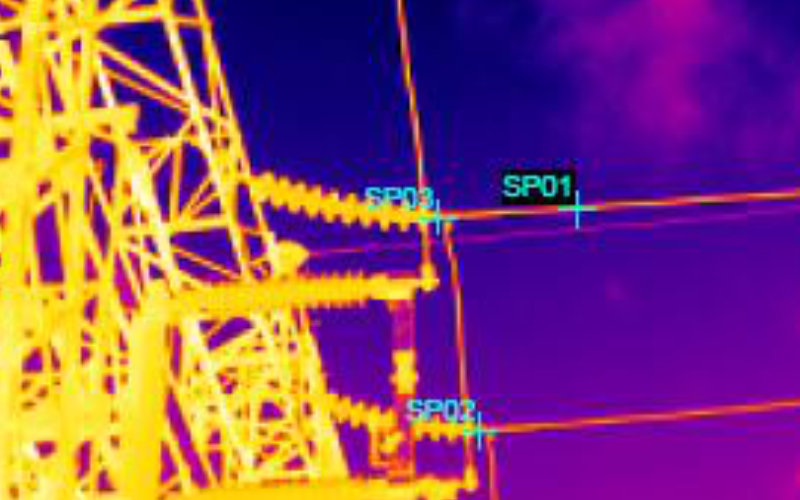

- Infrared Camera FLIR-T200

- TeraOhm 5 kV METREL-MI 2077

- TeraOhm 10 kV METREL-MI 3200

- Contact Resistance Meter

- Relay Testing

- Contact Timing

- Earth / Ground Tester FLUKE-1623

- Power Quality Analyzer 3 Phase Digital MultimeterFLUKE-337,287

- Electronic MultimeterFLUKE-287

- True-RMS Logging Multimeterwith Trend Capture FLIKE-289

- Telescopic Hot Stick

- Oil Transformer Purify Machine

- Voltage Detector

Thermal viewer services

Maintenance scope

115 kV to low voltages

For high voltages

- After the user’s meter to the transformers of high voltages

For low voltages

For low voltages

- From the low voltage transformer to the MDB

- Inside the MDB; which consists of the ACB, bus bar, and main circuit breaker of each section

Maintenance for high voltage equipment

Maintenance scope

- Conduct general, physical tests

- Check the size of the high voltage fuse

- Test the การปลด and switching of the high voltage equipment

- Test and clean the insulators

- Repair any hotspots known from observations through the infrared camera

- Compose a test report for clients

Load Break Switch maintenance

Maintenance scope

- Conduct general, physical tests

- Test the pressure of Gas SF6

- Test the opening-closing of the circuit and all moving mechanisms

- Test the resistance of the surface

- Test the resistance of the insulators

- Test the ground value

- Test the functions of main distribution board

MV Switchgear maintenance

Maintenance scope

- Conduct general, physical tests

- Test the opening-closing of the circuit and all moving mechanisms

- Test the resistance of the surface

- Test the resistance of the insulators

- Test the ground value

- Clean the inner and outer areas

Ring Main Unit maintenance

Maintenance scope

- Conduct general, physical tests

- Test the opening-closing of the circuit and all moving mechanisms

- Test the resistance of the surface

- Test the resistance of the insulators

- Test the ground value

- Clean the inner and outer areas

MDB maintenance

Maintenance scope

- Conduct general, physical tests

- Repair any hotspots known from observations through the infrared camera

- Test the electrical connection points by using torque wrenches at those points

- Test the opening-closing of the circuit and all moving mechanisms

- Test the resistance of the surface

- Test the resistance of the insulators

- Test the ground value

- Check the test equipment and system’s functions

- Clean the inner and outer areas

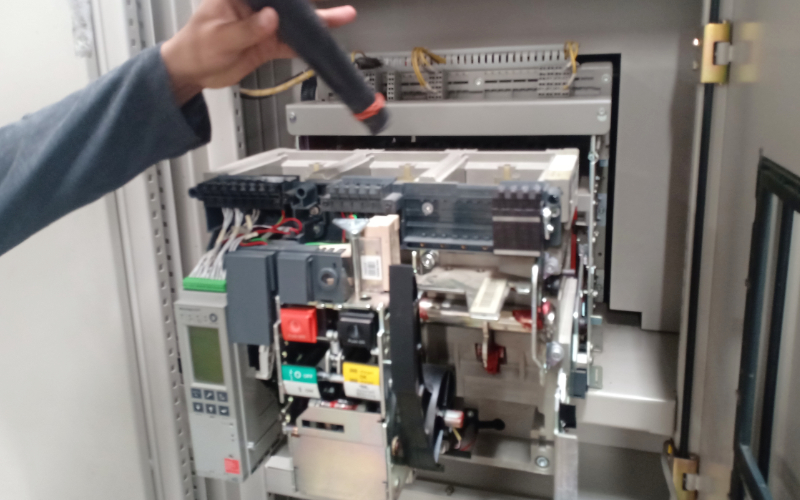

Air Circuit Breaker (ACB) testing services

Maintenance scope

- Conduct general, physical tests

- Test the mechanism set’s functions

- Test and measure the ACB’s contact resistance

- Test the Trip Unit’s functions

– Long-Time delay pick up current

– Short-Time delay pick up current

– Instantaneous delay pick up current

– Ground fault pick up current

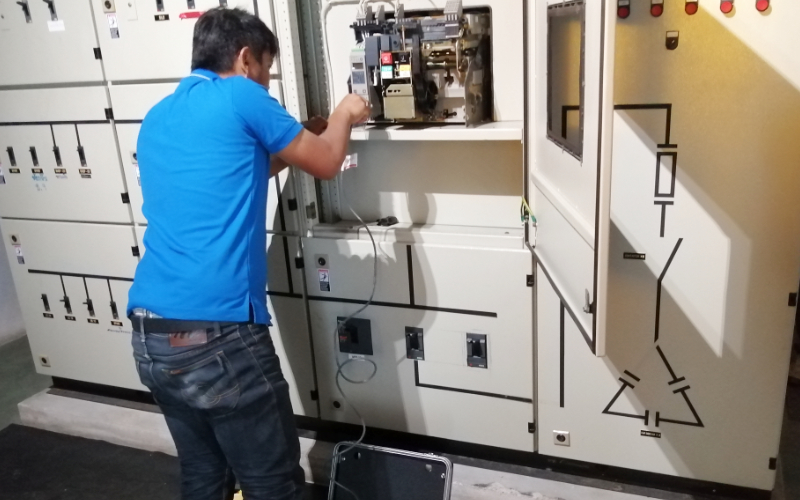

Automatic Transfer Switch (ATS) maintenance

Maintenance scope

- Test the ATS Control

- Test the operations of the Mechanical Interlock & Electrical Interlock of the Transfer set

- Test the electrical connection points by using torque wrenches at those points

- Test and adjust the values to be suitable with the usage and purposes

- Test the resistance of the surface

- Test the resistance of the insulators

- Test the ground value

- Test the operations of the measurement equipment and systems

- Clean the inner and outer areas

- Conduct general, physical tests

- Repair any hotspots known from observing through the infrared camera

Capacitor Bank maintenance

Maintenance scope

- Conduct general, physical tests

- Repair any hotspots known from observing through the infrared camera

- Test the electrical connection points by using torque wrenches at those points

- Test the operations of the Power Factor Controller

- Adjust and set the Power Factor to comply with the standard electrical criteria

- Test the HRC Fuse Link

- Check and test the operations of the Magnetic Contactor

- Check and measure the capacitance value of the Capacitor

- Test the ground value

- Clean all the inner and outer areas

Oil Type Transformer maintenance

Maintenance scope

- Measure the load

- Test the ground value ค่ากราวน์ at the transformer

- Check / change the absorbent

- Test the insulation class of the oil

- Test the insulation class of the coils

- Check the gaskets

- Check the transformer’s oil level

- Check the cleanliness of the bushing

- Check the transformer’s tap position

- Check the surge arrester and the high voltage fuse

- Check the Drop Out Fuse Cutout

Dry Type Transformer maintenance

Maintenance scope

- Measure the load

- Test the ground value ค่ากราวน์ at the transformer

- Test the insulation class of the coils

- Test the LV and HV connection points

- Test the tap connection points

- Clean the entire device

- Check the transformer’s tap position

- Check the fan’s operations

- Test the temperature alarm’s function

Ground value testing services

Maintenance scope

- Test the ground value in the user’s system at no more than 5 points